Listen to this chapter, narrated by the author.

Right vs. Perfect is Magic

by J. Allen | Updated 2023 | Originally Published Oct. 25, 2016

This may be a shock to you.

You might even accuse me of business heresy. I’ll give you the bottom line at the top of the page: perfection doesn’t matter if you never get things done. Don’t let perfect get in the way of right. To me, the evidence is clear: attentive, knowledgeable, committed people get things done quickly and with a high degree of excellence, doing it “right.”

They are the “right vs. perfect” high performers!

Freedom to Get Things Done

The concept of “right vs. perfect” is very freeing. It concentrates pressure on the things needed by those who most need them. It focuses on the recipients of the effort, the consumers of the output, and the delight of the end users. The result? Greater creativity and innovation, additional successful outcomes, more gratification…and considerably less frustration. And, yes, right vs. perfect gets things done faster, better, and more actionably for those who count most. It is the commonsense approach to excellence.

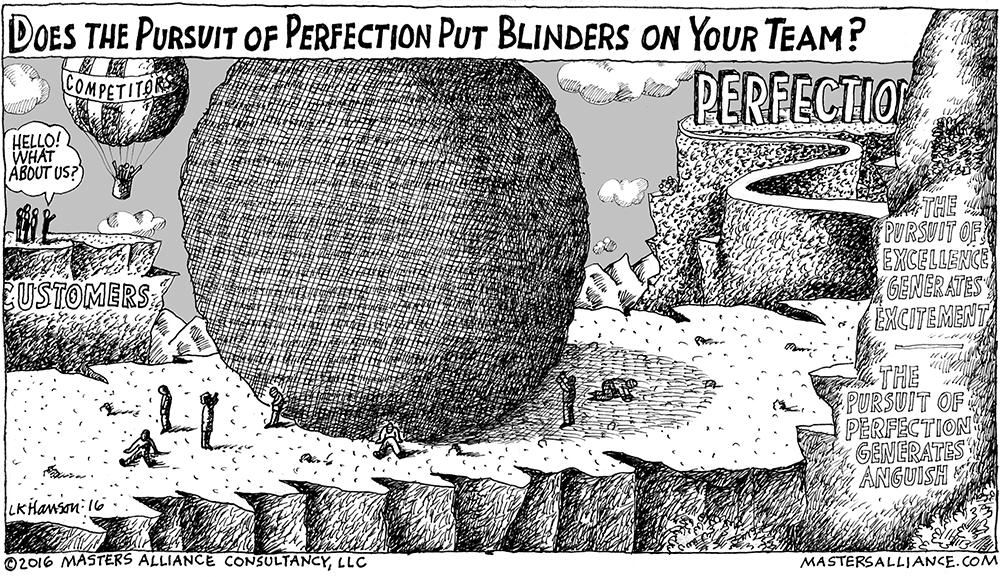

Leaders have no idea of the blinders they put on their organization when they mandate perfection without balancing real customer desires and aggressive timeliness. They don’t understand that a blanket investment in restrictive quality standards can lead to behaviors that dull their competitive edge. Leaders have forgotten what it is like to deliver a product that thrilled their clients but made their engineers grumble and their law- yers step up the approval pace.

We think it’s time to re-examine the case for a right vs. perfect business culture. Here are some insights into what that might look like.

Dangerous Implications

From a late 2018 Chicago Tribune article, we concluded that perfectionism is causing real suffering for young achievers. Perfectionism creates unrealistic standards and can breed anxiety, depression, and even suicidal thoughts. An irrational desire for perfect achievement can be stimulated by perceiving excessive expectations from others—and the connectivity and response expectations of today’s social media can add fuel to the fire. The desire to know everything can become obsessive, diminishing our time and freedom to reach out and work on creative team solutions.

Right vs. Perfect is About…

- getting things done, trying / testing things, taking controllable risks, overcoming fears …and taking action.

- being willing to notice improvement opportunities despite burdensome constraints (too much work, too much trouble, too many approvals, etc.)…and going ahead anyway, providing leadership.

- putting aside fears of looking stupid, being disrespected, or being resented for stirring up things best left alone…and getting it done anyway.

- considering and relating to others’ views (e.g., “Why doesn’t someone do something about this? There has to be a better way.”)…and using them as a rallying cry.

- engaging noticers as forces for change; remembering that they notice because they care about some thing and are dissatisfied; recognizing they have not yet, or recently, experienced the excitement, joy, and satisfaction of successfully improving some- thing…and making it happen.

- trusting others to know what needs to be done, how to do it well, and how to make the results scalable and sustainable.

Right vs. Perfect is NOT About…

- lowering standards (e.g., the pharmaceutical or aerospace industry).

- forgetting to strive for the best.

- eliminating the quest for perfection where needed (pharmacies, OR’s, aerospace, etc.)

- discrediting:

- Continuous Improvement, ISO, Quality, Malcolm Baldridge Quality Award, 6 Sigma.

- Good–Better–Best, pricing, upgrades, high standards, DIRTFT [dirtfoot]…do it right the first time

Client Example

Don’t believe it’s possible to have a more engaged team, happier customers, and a faster speed to market? Here’s a story of how a company applied some right vs. perfect principles and still maintained high quality in their outcomes.

Situation: AlliedSignal Aerospace Inc. was utilizing 112,000 individual parts in an extremely complex aerospace effort involving 7,500 employees, 6 international unions, and a 3-million-square-foot factory. The organization had a history of high performance and excellent leadership, having held an industry-leading on-time delivery rate of 92 percent over the previous 20 years. Jack Knuth, the company president, knew it needed to break through to a new performance level to maintain its competitive leadership position. A dramatic improvement in on-time delivery was necessary while maintaining the “perfect” quality required in certain parts of the aerospace industry.

- The senior management team agreed to bet its entire bonus on achieving three gold rings…in only 6 months! Next-level management, 170 supervisors, and over 800 engineers, scientists, and other professionals became engaged in the goal.

- Every hourly employee began participating in large meetings and breakout groups to identify what individual and group goals could be accomplished. Jack agreed to kiss a duck if the company’s gold rings were achieved (primarily focused on 100 percent on-time delivery).

- A “barrier removal war room” was established with a meeting every Tuesday afternoon at 4:00—inviting any employee or manager to come to the room, have some pizza, and offer a barrier they had attempted to remove but needed senior management assistance. The first few weeks, the line was down the hall and around the corner, and the meetings went into the evening.

- A 1-800 extension was set up for employee call-in requests. The senior management group became the “barrier removal squad” with a promise to respond to all requests in 24 hours, rotating responsibilities each After a while, the supervisors, managers and VPs learned to listen better and remove barriers before they gained executive attention.

- Six months after effort initiation, on-time delivery had reached 99.89 percent and would remain above 99 percent for the following years. Now, we all know on-time delivery turnaround can be achieved with increased costs, reduced quality, and increased scrap… but this organization did so with reduced quality exceptions, reduced scrap, and zero increase in hours!

- All gold rings were achieved. At an all-hands results celebration, Jack did indeed kiss a duck near the back end. An hourly union employee addressed the auditorium of several hundred people: “I may get in a lot of trouble, but now that I am listened to and allowed to make improvements, I never want to work any other way.”

Does Your Organization Get Things Done?

Help your organization gain a competitive advantage. Start with diagnostic conversations. Ask questions like…

- Is our organization really a world-class high performer?

- What’s preventing us from this high performance level?

- What are our greatest obstacles to achieving high performance?

Once all the niceties and standard answers are pushed out of the way, start digging into the why of the issue. Why aren’t we a high-performing organization? A very common response to the third, fourth, or fifth why is because we get too little done, we can’t get things done quickly, or the stuff we get done is no longer on the cutting edge.

Leaders call out the names of quality and perfection as the drivers of why they must go slow to bring things to market. So, pop the radical question: “Why obsess with perfection when right will get you to market faster, excite customers, and gain competitive advantage?” Everything learned in a Lean Six Sigma, Quality, and ISO world has driven leaders toward perfect. The anguish of perfection seems to appear when our conscientious pursuit of getting done with excellence gets crossed with our natural aptitude and the inherent desire to be perfect before making a decision.

In the early days of the quality movement, W. Edwards Deming made it clear that quality was about statistically clear adherence to variance limits defined by a necessary goal—not that all variation would be removed (an impossible task). Make sure your quality goals are right vs. perfect—right for the customer, marketplace, and greatest positive competitive impact!

What You Can Do…

Are you interested in getting more things done, trying/testing things, taking controllable risks, overcoming fears, taking action…seeing more leadership at all organization levels? Want a more engaged employee and customer base? Want to shed the burden of perfection when it’s not required? Explore how a right vs. perfect approach to competitive advantage can work for your organization, providing the tools and framework to help your team think and lead differently. Here are a few ideas to help you get started:

- Does your organization have a good understanding of the company’s customers and their needs?

- Do groups offer solutions that anticipate or create customer needs?

- Do you as a leader encourage disruptive innovation? Do other leaders?

- Do you or others obsess with perfection in your ideation or implementation processes?

- Does your organization exhibit a bias for action and a sense of urgency, quickly getting offerings to market? Test your team on a “get-things-done barometer.”

- Test your organization on an “improvement urgency scale.”

We Can Help

Want a more engaged employee and customer base? Want to shed the burden of perfection when it’s not required? If you do, Masters Alliance can help you see how a “right vs. perfect” approach to building a competitive advantage can work for your organization.

We can help bring these tips to life with your organization – providing the tools and framework to help your team think and lead differently. We’ve helped dozens of our clients implement this new way of leading their organizations.

Learn more about where your organization stands. Master’s Alliance has two simple assessment tools:

- Test your team on the Masters Alliance “Get Things Done Barometer”

- Test your organization on the Masters Alliance “Improvement Urgency Scale. Consider this idea: Your teams are engaged and want to deliver great customer service, but YOU / your leaders might be stopping it from happening…causing others to hesitate rather than act!

Masters Alliance is a 30-year strategic management consulting firm that has helped more than 120 client organizations in over 20 industries in 13 countries gain a competitive advantage in their market. We help organizations develop and implement unique business strategies that work – faster than our clients ever thought possible.

We help clients achieve significant performance gains from a breakthrough understanding of their customers / patients / clients and markets.

To privately start this revealing assessment process, give J. Allen a call at 952-831-7300, or send us an email.